Counterfeit parts are more common than many people believe, and this is certainly true for electronics components. These counterfeit parts decrease customer satisfaction and increase costs for legitimate manufacturers like ACDi. That is why we have a strict quality control system in place to prevent counterfeit parts from entering our supply chain.

The biggest issue with counterfeit parts is not that they don’t work; it’s that they sometimes work. This makes it extremely difficult to know when and if they will fail. These parts might work during testing or work for a long period of time before failing. Imagine what could happen if an electronic device that is crucial to the health and safety of the general public contained counterfeit parts. When these systems fail, the results could be disastrous.

Identifying Counterfeit Parts

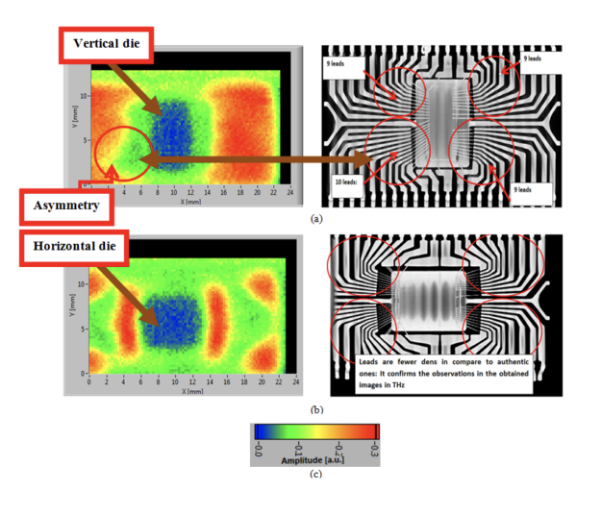

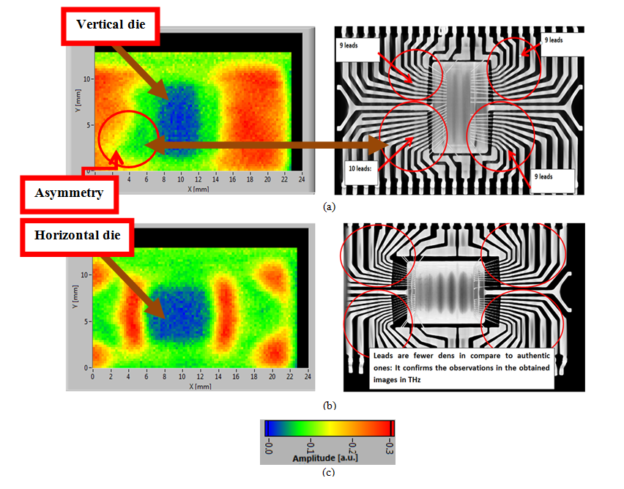

Not all “bad” parts are necessarily counterfeit. Counterfeit electronics parts are not easy to identify even with advanced methods, so it’s important to also have quality control processes where all parts are inspected through a variety of security measures. Some of the methods that suppliers use to determine if a part is counterfeit include:

- Visual inspection by optical microscopy

- X-ray

- De-capsulation

- Scanning acoustic microscopy

- FTIR

- Electrical test

- Discussions with OCM

Integrated circuits are one of the most frequently counterfeited parts. Common forms of counterfeits include low cost parts that have had their numbers replaced with those of higher cost parts, and cheap copies of parts that are manufactured in other countries. Read more

Source: www.acdi.com